OUR PHILOSOPHY

We use the naturally occurring shrinkage of the log to our advantage with our ButtSpline® technology to make your log home air tight.

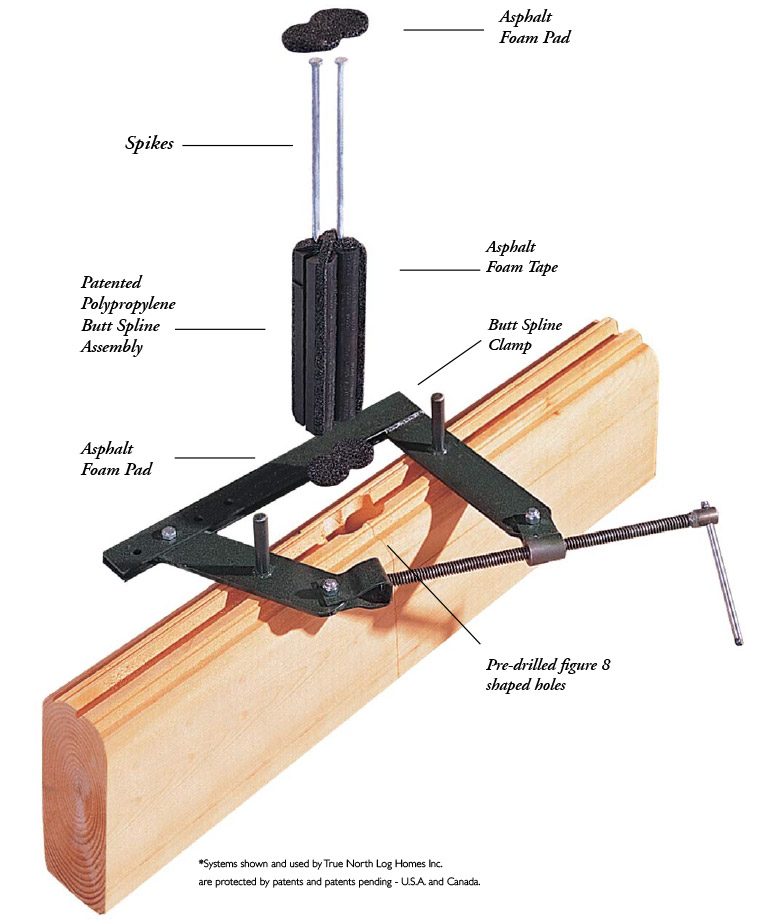

BUTTSPLINE® ASSEMBLY

- Two holes are drilled in the end of each log to create a figure-eight shape as they butt together in a wall assembly.

- A custom made ButtSpline® clamp is inserted into pre-drilled holes and pressure is applied to draw the joint together.

- An asphalt-impregnated figure eight foam pad is installed at the bottom of the holes.

- A two-piece polypropylene assembly is wrapped with asphalt foam tape and then dropped into the holes.

- Two 10-inch common spikes are driven into the two-piece assembly, wedging it apart, tightening the joint.

- Another asphalt-impregnated figure eight foam pad is installed on top of the assembly.

- The clamp is removed.

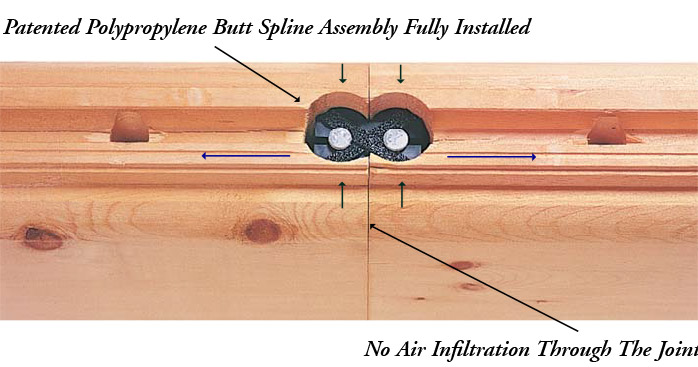

OUR SECRET

The natural shrinkage in the width of the log (green arrows).

The log squeezes on the radius of the ButtSpline®. At the same time (shown with blue arrows) the log shrinks lengthwise, pulling on the ButtSpline® causing the joint to tighten over time.

*Systems shown and used by True North Log Homes Inc. are protected by patents and patents pending – U.S.A. and Canada.